Deflection gauges, "mandrels", are used to test flexible sewer pipes for out-of-roundness (deflection).

This testing ensures flexible pipe has been properly bedded and back-filled to give optimum performance (ASTM Designation D2321-89).

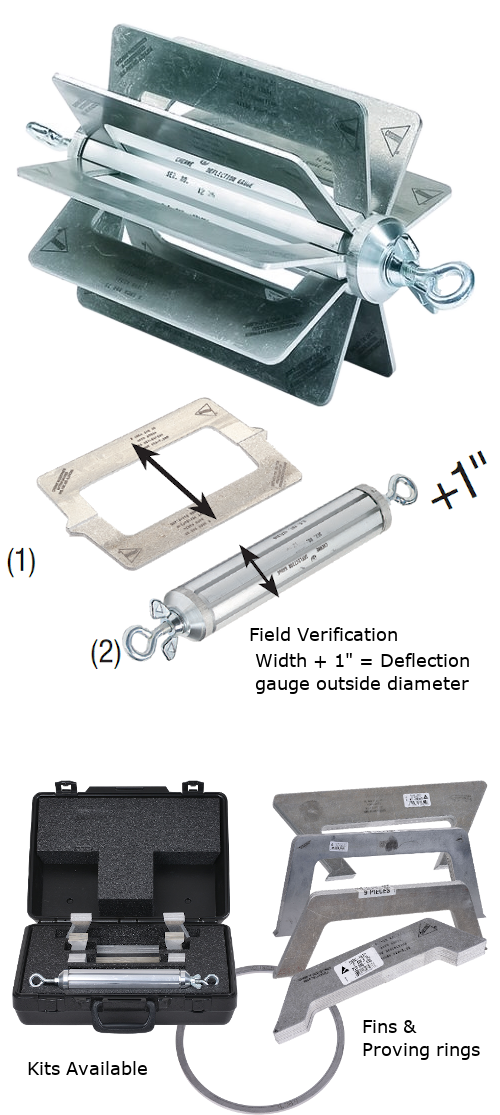

Adjustable Aluminum Deflection Gauges

Utilizes a 9 arm design to ensure the pipe is tested accurately. Sized to within .01" to meet ASTM requirements.

Constructed of lightweight aluminum, gauges will not rust and are up to 75% lighter in comparison to steel models.

Economical and versatile patented design, features interchangeable fins for different pipe sizes.

Field Verification: Cherne's Aluminum Fin Style Deflection Gauges are designed to be field verified by inspectors

without the use of a proving ring. Simply place two fins end-to-end as pictured below (1) and measure the width.

Add one inch to the mandrel (2) and you have the outside dimension of the gauge. Using this method simplifies the

inspector's job of verifying sizes on deflection gauges.

Features:

- Lightweight, corrosion-resistant

- Field-verifiable without a proving ring

- Assembles without tools

- All sizes fit through standard 24" manhole

- Fins for 4"-15" gauges have skid size equal to the nominal pipe size-gauge will meet regional codes and will not tip in the line

- Nine-fin design ensures testing accuracy

- Open design allows gravel and debris to pass-through

- Kits covering pipe sizes 6-10" or 8-12" are available

Sizes & Specifications

Sizes & Specifications

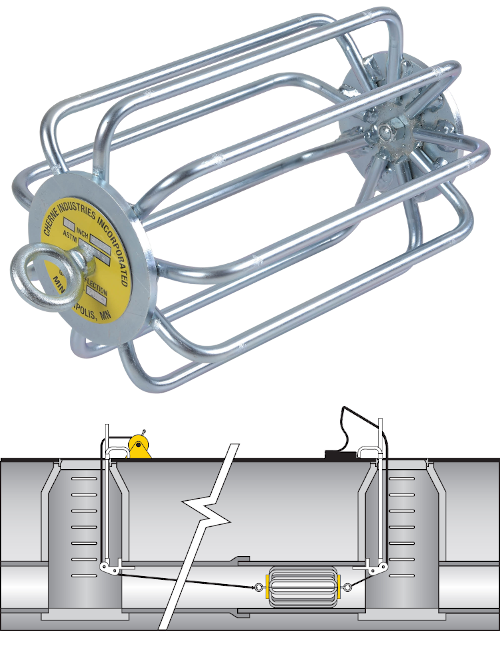

Steel Gauges

Designed to allow gravel and debris to pass through easily.

Other kinds of gauges have a tendency to get hung up on rocks and obstructions causing a

deflection test to fail even though the pipe is within deflection tolerances creating a

great expense for the contractor.

Features:

- Durable steel construction for municipalities that requires steel mandrels

- Zinc plated which resists rust and corrosion

- Nine-arm design ensures testing accuracy

- Open design allows gravel and debris pass-through

- Conforms to mandrel sizing specification:

Blade length is equal to or greater than the nominal pipe size to conform with mandrel sizing specifications

- 5% & 7.5% Gauges for SDR-35 Pipe per ASTM D3034 (4"-15" Dia.)

- 5% & 7.5% Gauges for SDR-26 Pipe per ASTM D3034 (4" -15" Dia.)

- 5% & 7.5% for PS 46 (SDR-35) Pipe per ASTM F679 (18" - 48" Dia.)

- 5% & 7.5% for PS 115 (SDR-26) Pipe per ASTM F679 (18" - 48" Dia.)

Sizes & Specifications

Sizes & Specifications

Manhole Winch & Manhole Jack

Manhole Winch:

- Drags plugs in leak location testing, deflection gauges

- Feeds Jet-Ball down line for sewer cleaning

- Normal pull-strength up to 550 pounds

- 500 feet of 3/32" diameter steel cable

Manhole Jack (Hose Guide):

- Guides air hoses and cables at pipe invert in manhole

- Zinc-plated for corrosion resistance

- Fits pipe 5"-24"

- Includes eye bolt for securing rope and ease of retrieval

One Piece Deflection Gauge System

Custom Sizes & Specs Always Available on Deflection Gauges & Proving Rings!

Features:

- Lightweight T6061 Aluminum Construction

- Available in Steel

- High Clearance to Avoid Getting Stuck on Debris

- Permanently Marked with Size & Deflection - Won't Scrape Off - Letters Cut into Fins

- One Piece Forged Eyebolts

- Snap-Lock Fins

- Fits down 24" Manholes

- Proving Rings Available for All Sizes

- No Tools Needed - No Bolts, Nuts, or Pins!

- Size & Deflection Cut into Ring - Will not Scrape Off

- 5% & 7.5% Deflection Gauges for SDR-26 Pipe (Sizes from 6" thru 30")

- 5% & 7.5% Deflection Gauges for SDR-35 Pipe (Sizes from 4" thru 27")